In materials science and engineering, accurate mechanical performance testing is crucial for ensuring product quality and performance. As a core equipment in material testing, ZTTEST Universal Tensile Testing Machine has been widely adopted in research institutes, quality inspection organizations, and corporate laboratories due to its high precision, multifunctionality, and user-friendly operation, providing reliable data support for material R&D, product design, and quality control.

Technical Specifications: Precision and Reliability for Diverse Needs

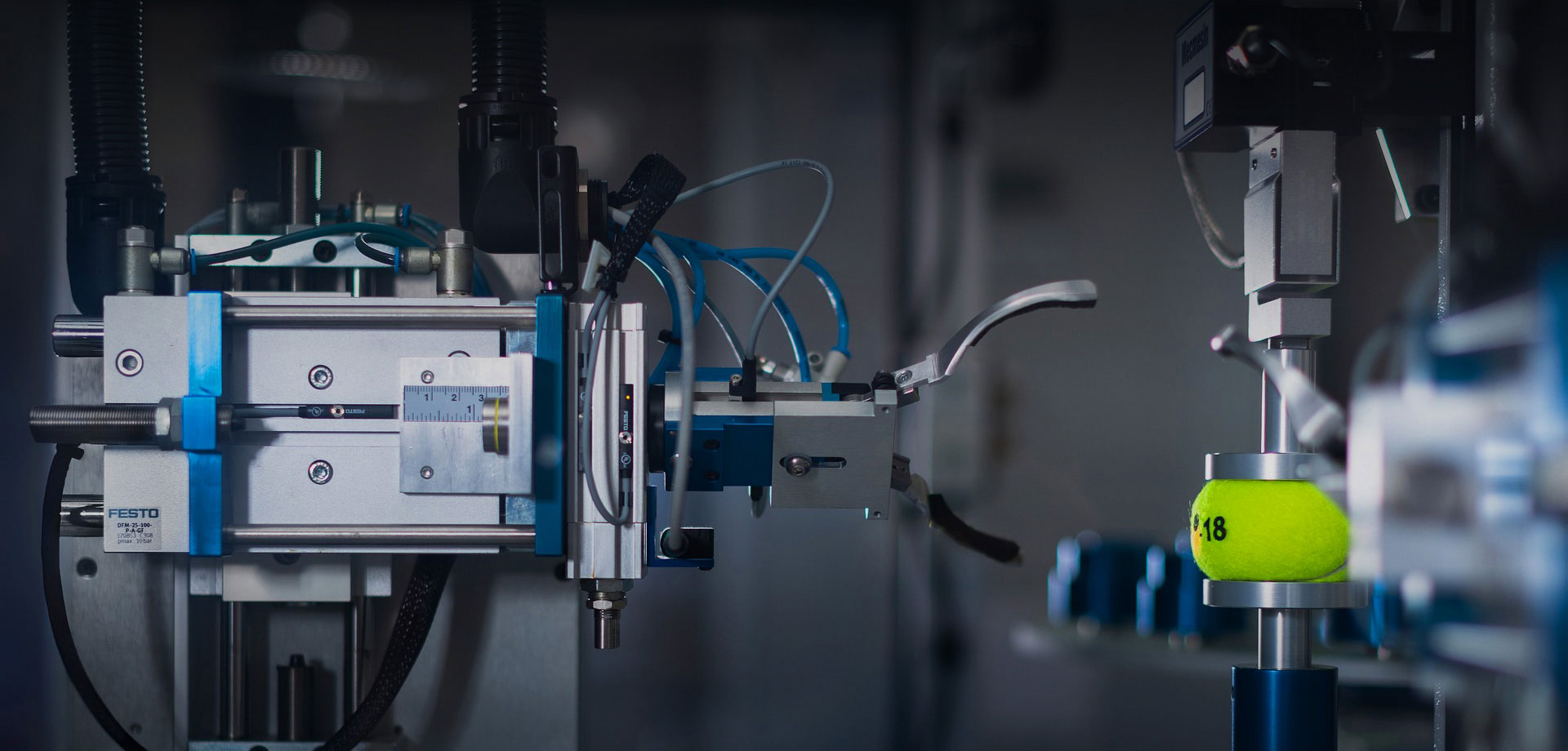

ZTTEST Universal Tensile Testing Machine incorporates advanced sensor technology and control systems to ensure high accuracy and reliability of test data. Key technical parameters include:

Maximum Test Force: Covers a wide range from micro-force to ultra-high force, meeting various material testing requirements

Test Speed: Stepless speed regulation enables precise testing at multiple velocities

Displacement Measurement: High-precision encoder ensures accurate displacement tracking

Data Acquisition: High-speed data acquisition system records real-time force, displacement, and deformation data

Software: Powerful testing software enables automated control, data analysis, and report generation

Industry Applications: Extensive Coverage, Driving Industrial Development

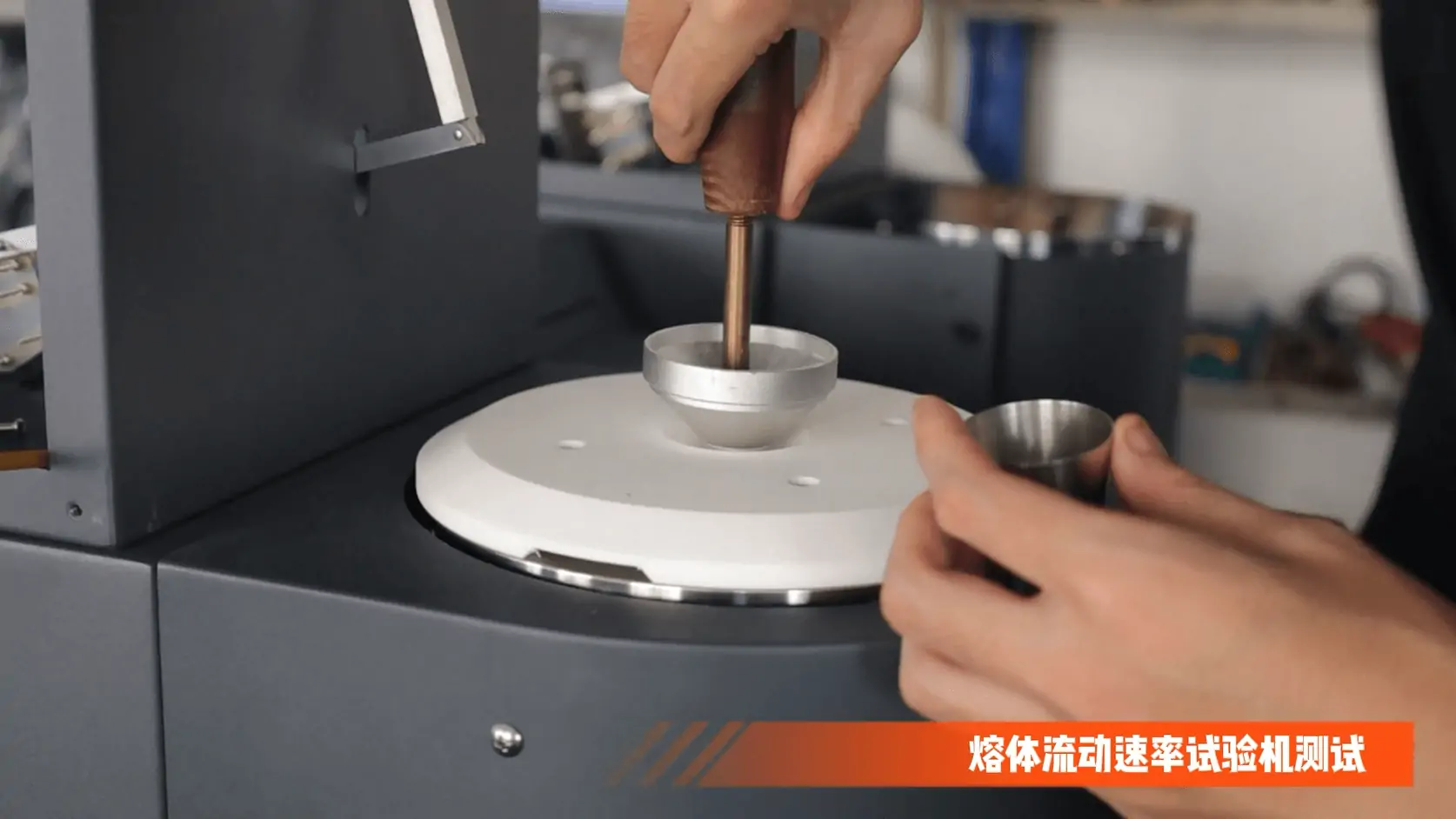

ZTTEST Universal Tensile Testing Machine plays vital roles across multiple industries:

Metals: Evaluates tensile, compression, bending, and shear properties for metal product development

Non-metallics: Tests plastics, rubber, ceramics, and composites under various environmental conditions

Construction Materials: Verifies mechanical properties of concrete, steel bars, and timber for structural safety

Textiles: Measures tensile strength, tear resistance, and bursting strength of fibers and fabrics

Packaging Materials: Assesses tensile, tear, and puncture resistance of paper, cardboard, and films

Why Choose Us: Professional Services, Trustworthy Partnership

ZTTEST is committed to delivering high-quality testing machines and comprehensive after-sales support. With professional R&D teams and extensive industry experience, we offer:

Customized solutions tailored to specific requirements

Turnkey services including installation, commissioning, training, and maintenance

Choose precision. Choose innovation. Choose ZTTEST.

Contact us today for product details and service information.