Universal Tensile Testing Machine: A Key Equipment for Material Performance Testing

Introduction

In the fields of materials science and engineering, the accuracy and reliability of testing equipment directly impact product quality and research efficiency. Among these, the universal tensile testing machine, as a versatile and precise device for testing tensile, compressive, and bending properties of materials, has become an essential instrument in research, manufacturing, and quality control. This article provides a detailed introduction to the principles, main functions, applications, and future trends of universal tensile testing machines.

Basic Principles of Universal Tensile Testing Machines

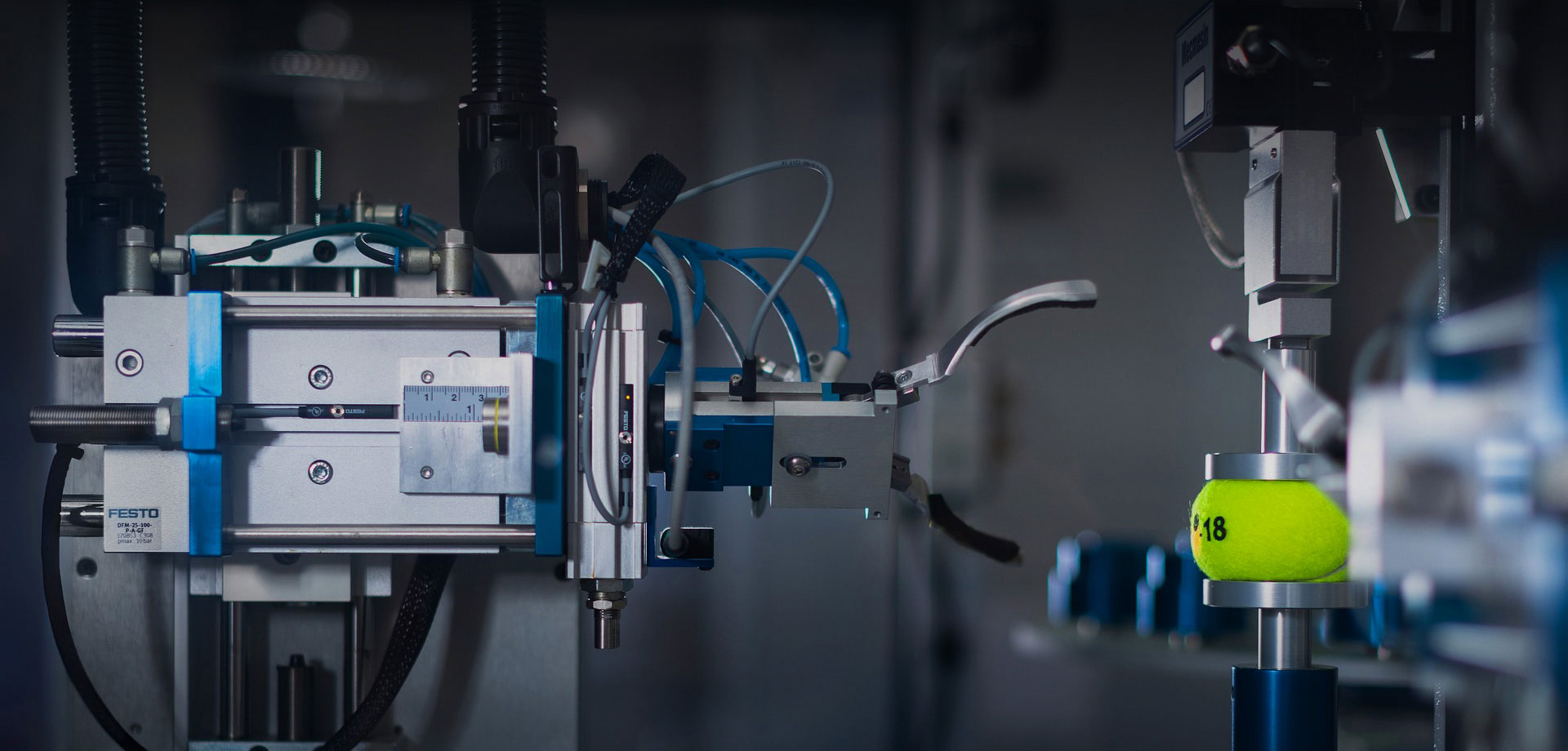

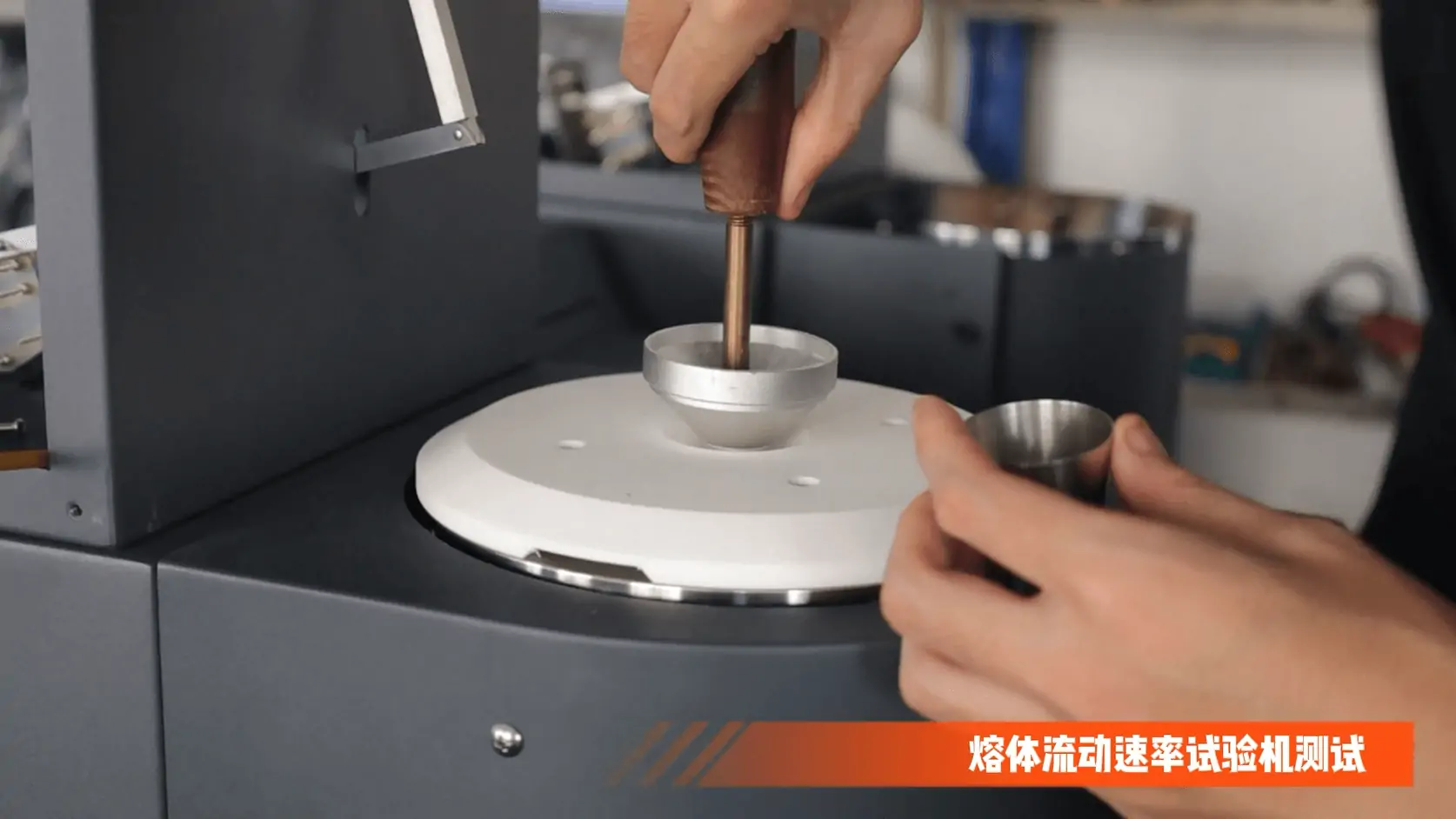

Universal tensile testing machines primarily use hydraulic, electric, or servo systems to generate controllable forces. Through force sensors and displacement sensors, they accurately measure the deformation of materials under various loads. During testing, the machine records stress-strain curves, enabling the determination of key mechanical properties such as yield strength, tensile strength, and elongation. This precise data collection capability provides reliable support for material science research and serves as a critical basis for industrial product quality control.

Main Functions and Features

1. Multifunctional Testing

Universal tensile testing machines can perform not only tensile tests but also compression, bending, shear, and other mechanical tests. Their flexibility makes them suitable for a wide range of materials, including metals, plastics, rubber, and composites.

2. Precise Measurement System

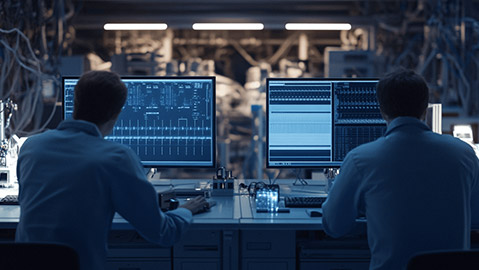

Equipped with high-precision sensors and data acquisition systems, these machines can record test data in real time. Advanced software algorithms further process and analyze the data, generating stress-strain curves and other relevant reports, providing intuitive and scientific insights for material performance analysis.

3. High Automation

Modern universal tensile testing machines are mostly equipped with automatic control systems, enabling them to complete preset testing tasks autonomously. Operators only need minimal adjustments, and the machine can carry out fully automated testing processes, significantly improving testing efficiency and data reliability.

Applications

1. Material Research and Development

In the development of new materials, universal tensile testing machines can quickly and accurately measure fundamental mechanical properties, guiding researchers in optimizing material composition and structure to achieve technological breakthroughs.

2. Quality Control

In the manufacturing sector, quality inspection is a critical step to ensure product safety and performance. Universal tensile testing machines are widely used to test the mechanical properties of raw materials and finished products, ensuring compliance with national or industry standards and safeguarding consumer safety.

3. Engineering Structure Evaluation

In projects such as construction, bridges, and aviation, material durability and strength are key indicators. By conducting simulated extreme load tests with universal tensile testing machines, the safety performance of structures under long-term use or extreme conditions can be predicted in advance, providing strong support for engineering design and maintenance.

Development Trends and Prospects

With continuous technological advancements, universal tensile testing machines are evolving toward higher precision, greater automation, and increased intelligence. Future devices may integrate more sensor technologies and big data analytics, enabling real-time monitoring and remote operation. Cloud platforms could facilitate data sharing and analysis, offering more comprehensive solutions for cross-disciplinary material research and engineering applications.

Moreover, the rapid development of new materials and energy industries imposes higher demands on testing equipment. Ensuring testing accuracy and reliability while improving testing speed and adaptability will remain a key focus for continuous improvement and innovation among equipment manufacturers.

Conclusion

As a vital tool for testing the mechanical properties of materials, universal tensile testing machines have played an irreplaceable role in research, production, and engineering. With ongoing technological progress and expanding applications, their future prospects are promising. The pursuit of higher precision and efficiency in testing equipment will provide solid support for advancing the entire field of materials science and engineering technology.