The Melt Flow Indexer (MFI) is a laboratory instrument used to determine the melt flow of plastic materials under specific temperature and pressure conditions. Melt Flow Rate (MFR) or Melt Flow Index (MFI) is an important indicator of the flow of plastics in the molten state and is widely used in plastics production, quality control, research and development, and standardized testing. By testing the MFR, the processability, melt flow and final product properties of plastics can be evaluated.

I. Working Principle of Plastic Melt Flow Rate Tester

Plastic melt flow rate meter mainly through the following steps for measurement:

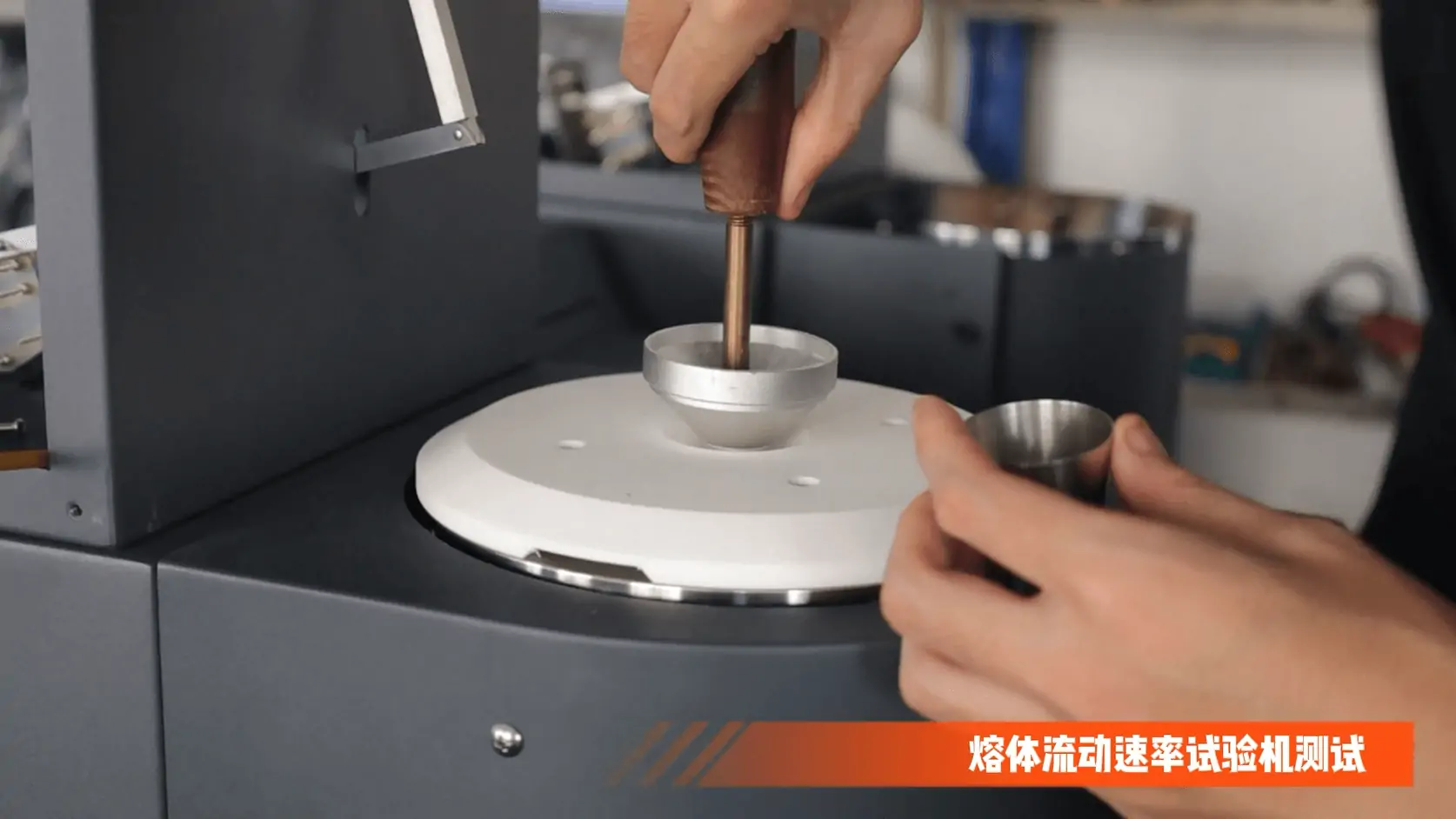

1. Sample Preparation: A certain mass of plastic granules or pellets is put into a heating cylinder and set to be heated to a specific temperature.

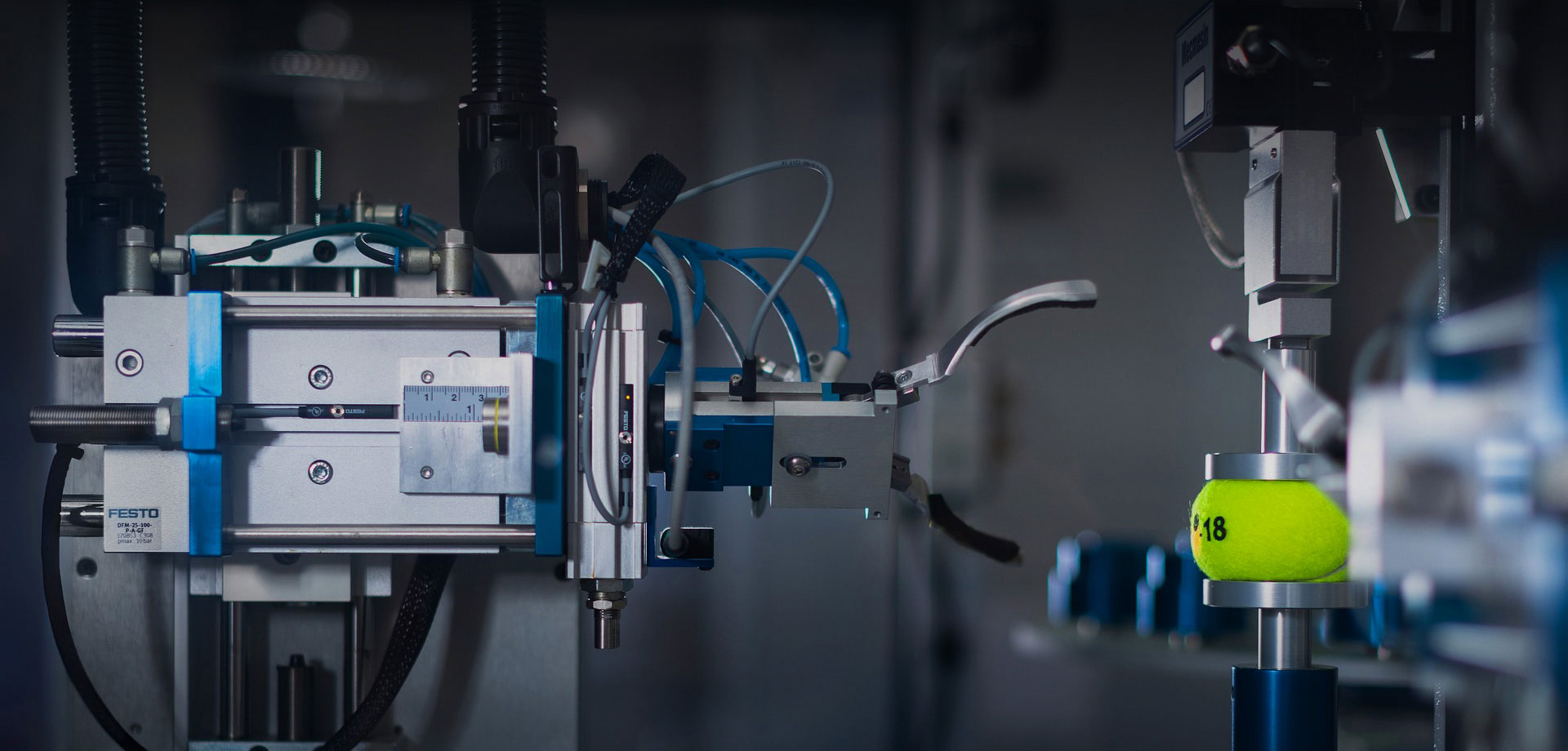

2. Heating and Pressure: The device heats the plastic to a specified melting temperature by means of a heating cylinder and applies a certain pressure to force the plastic melt through a standard orifice.

3. Measurement of flow: The mass of melt passing through the standard orifice is recorded within a certain period of time (usually 10 minutes). The value of this flow rate is the Melt Flow Rate (MFR).

According to different standards and requirements, the MFR meter can be set up with different test conditions (e.g. temperature, pressure and orifice diameter) to adapt to the testing of different types of plastics.

Second, the main features of the plastic melt flow rate meter

1. High precision measurement

Plastic Melt Flow Rate Tester is able to provide high precision flow measurement by precise heating system and pressure control system. The device supports different temperature control and load conditions to ensure the accuracy and stability of the test results.

2. Intelligent operation interface

Modern plastic melt flow rate tester is equipped with intelligent operation interface, which simplifies the operation process of the equipment. Users can use the touch screen or computer software to set the temperature, pressure, test time, etc., and can monitor the test data in real time.

3. Multi-functional testing capability

In addition to the basic melt flow rate measurement, the equipment can also test the melt volume flow rate (MVR) and other related parameters according to different needs, in order to adapt to the testing needs of different plastics.

4. Standards compliance

Plastic Melt Flow Rate Tester usually conforms to ISO 1133, ASTM D1238 and other international standards to ensure the authority and comparability of test results.

Third, the main use of plastic melt flow rate meter

1. Plastic production and quality control

In the plastic production process, through the melt flow rate meter to test the liquidity of raw materials or finished products, to help manufacturers optimize the processing conditions, to ensure that the production of plastics in line with quality standards.

Plastics with high MFR values usually have better processing fluidity, while plastics with low MFR values usually have higher strength and rigidity.

2. New material development

When developing new plastic materials, MFR can evaluate the effect of different component formulations on the flow of plastics, helping material scientists and engineers to optimize material formulations and improve the processability of new materials.

3. Physical testing and standardized testing

Plastic Melt Flow Rate Tester is widely used in the plastics industry for quality inspection and standardized testing to ensure that products comply with industry and international standards (e.g. ISO, ASTM, etc.).

4. Plastic recycling and reuse

In the plastics recycling industry, the processability and reuse value of recycled plastics can be assessed by testing the flowability of recycled plastics.

IV. Summary

The role of plastic melt flow rate meter in plastic production, research and development and quality control is crucial. By choosing the right equipment, it can not only improve production efficiency, but also ensure product quality and material reliability. When purchasing, enterprises should choose the equipment that meets the standard, high precision and convenient operation according to their own needs, and ensure that manufacturers provide good technical support and after-sales service.