------From Principles to Purchasing: A Comprehensive Guide to Choosing Cost-Effective Equipment

Keywords: Plastic Pendulum Impact Tester

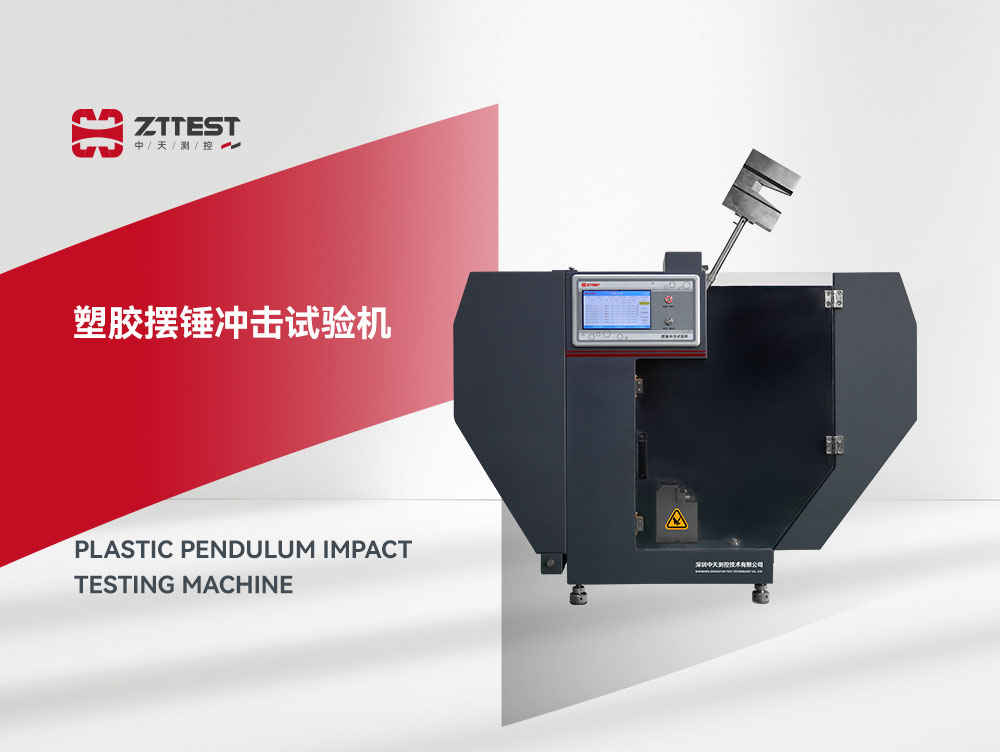

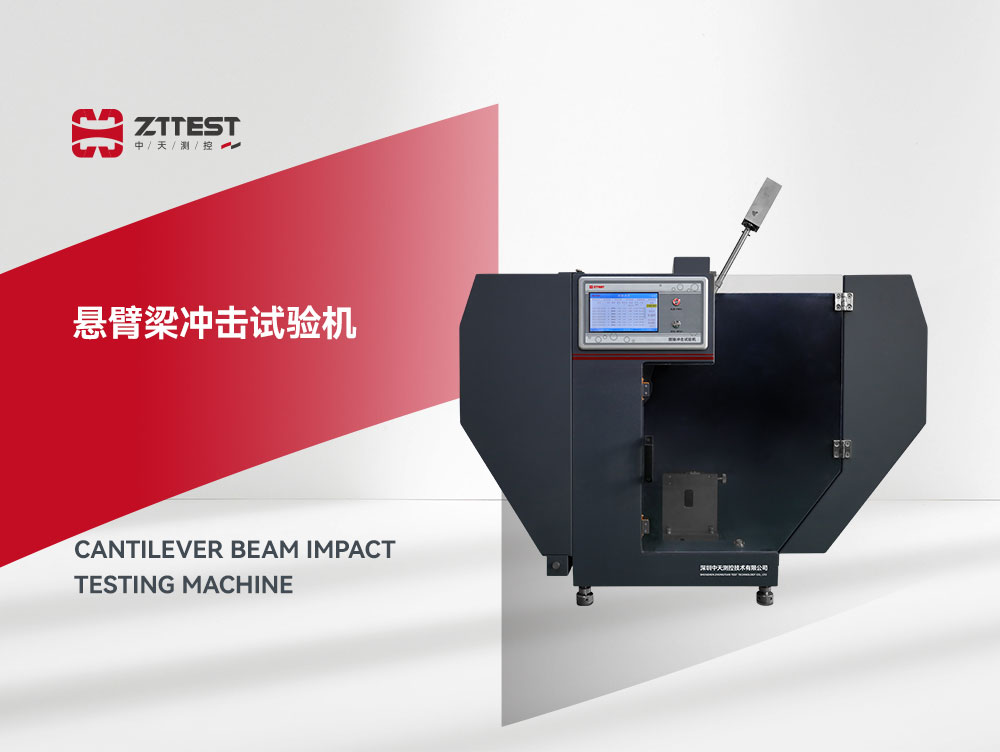

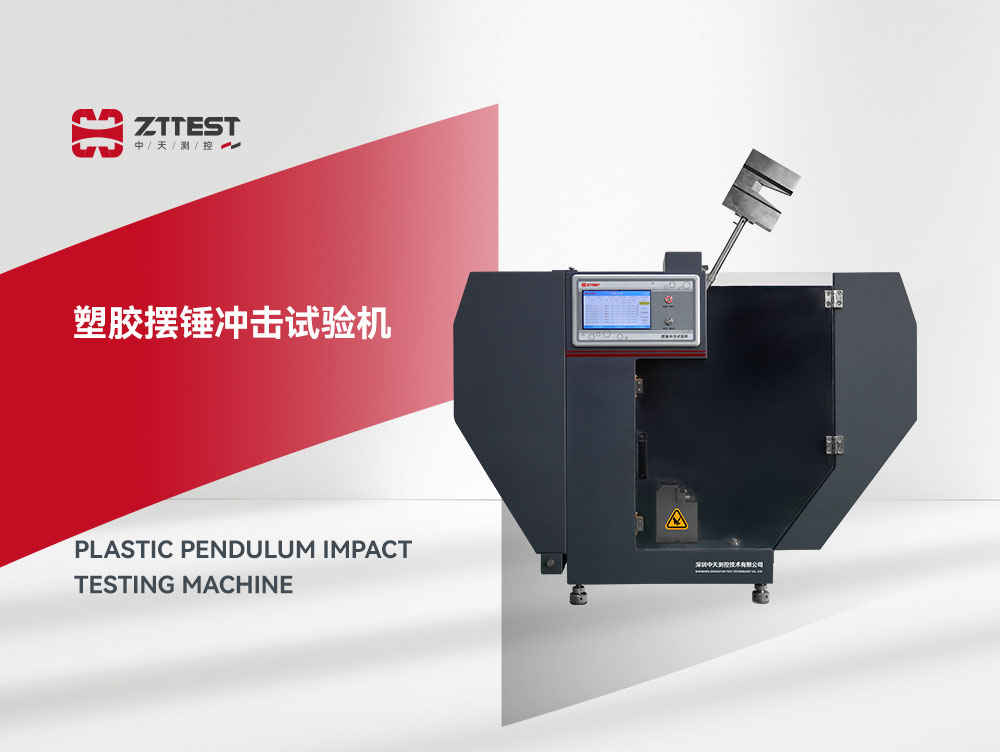

In industries such as plastics, rubber, and composite materials, the impact resistance of materials is one of the key indicators for measuring product quality. Whether it's automotive components, electronic housings, or packaging materials, rigorous impact testing is required to verify their reliability. The Plastic Pendulum Impact Tester is the core testing equipment in this field. This article provides a comprehensive reference for enterprises and quality inspectors, covering equipment principles, application scenarios, and purchasing guidelines.

1. Equipment Overview: Core Functions of the Plastic Pendulum Impact Tester

1.1 Definition and Working Principle

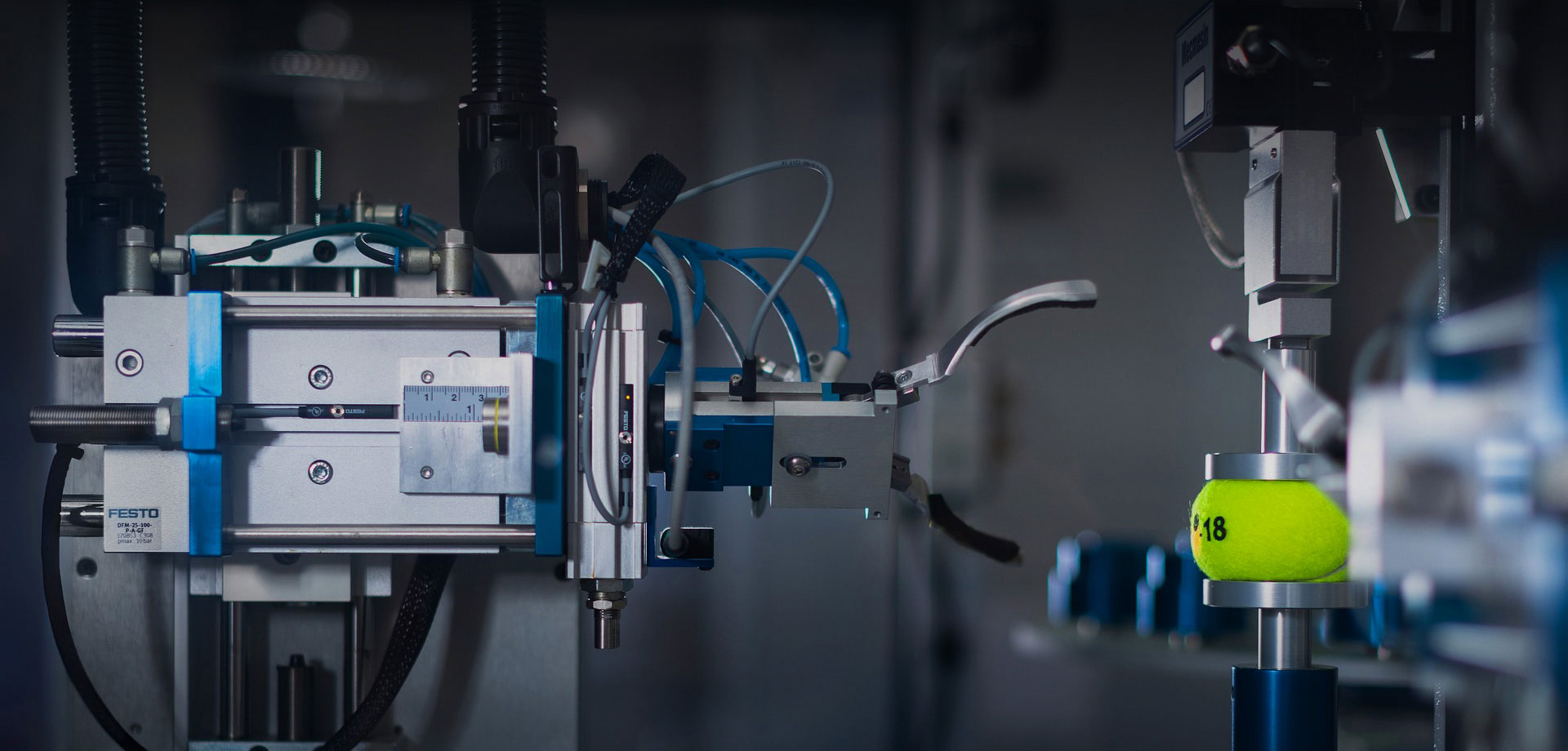

The Plastic Pendulum Impact Tester is a specialized instrument that measures the impact strength of materials by releasing a pendulum to strike a sample. Its core principles are:

The pendulum is released from a preset height, strikes the sample, and swings to the other side. The energy loss is used to calculate the material's impact toughness.

Test results are expressed in terms of impact strength (unit: kJ/m² or J/m), directly reflecting the material's fracture resistance.

1.2 Key Technical Parameters

Impact Energy Range: Common models cover 0.5J to 50J, suitable for materials of different thicknesses and hardness levels.

Pendulum Pre-lift Angle: Standard is 150°, with some devices supporting angle adjustment.

Testing Standards: Supports international standards such as ISO 179, ASTM D6110, and GB/T 1043.

Data Output: Automatically records impact energy, absorbed energy, impact speed, and other parameters, with support for data export and printing.

1.3 Application Fields

Plastic Products: Impact resistance testing of injection-molded parts such as PP, ABS, and PC.

Rubber Materials: Toughness evaluation of automotive seals and shock absorbers.

Composite Materials: Performance verification of glass fiber and carbon fiber-reinforced materials.

2. Equipment Usage: Operating Procedures and Precautions

2.1 Standard Operating Steps

Sample Preparation: Cut materials to standard dimensions (typically 80mm×10mm×4mm), ensuring the surface is free of scratches.

Equipment Calibration: Check the energy loss of the pendulum under no load (should be ≤1%) and adjust the base to ensure it is level.

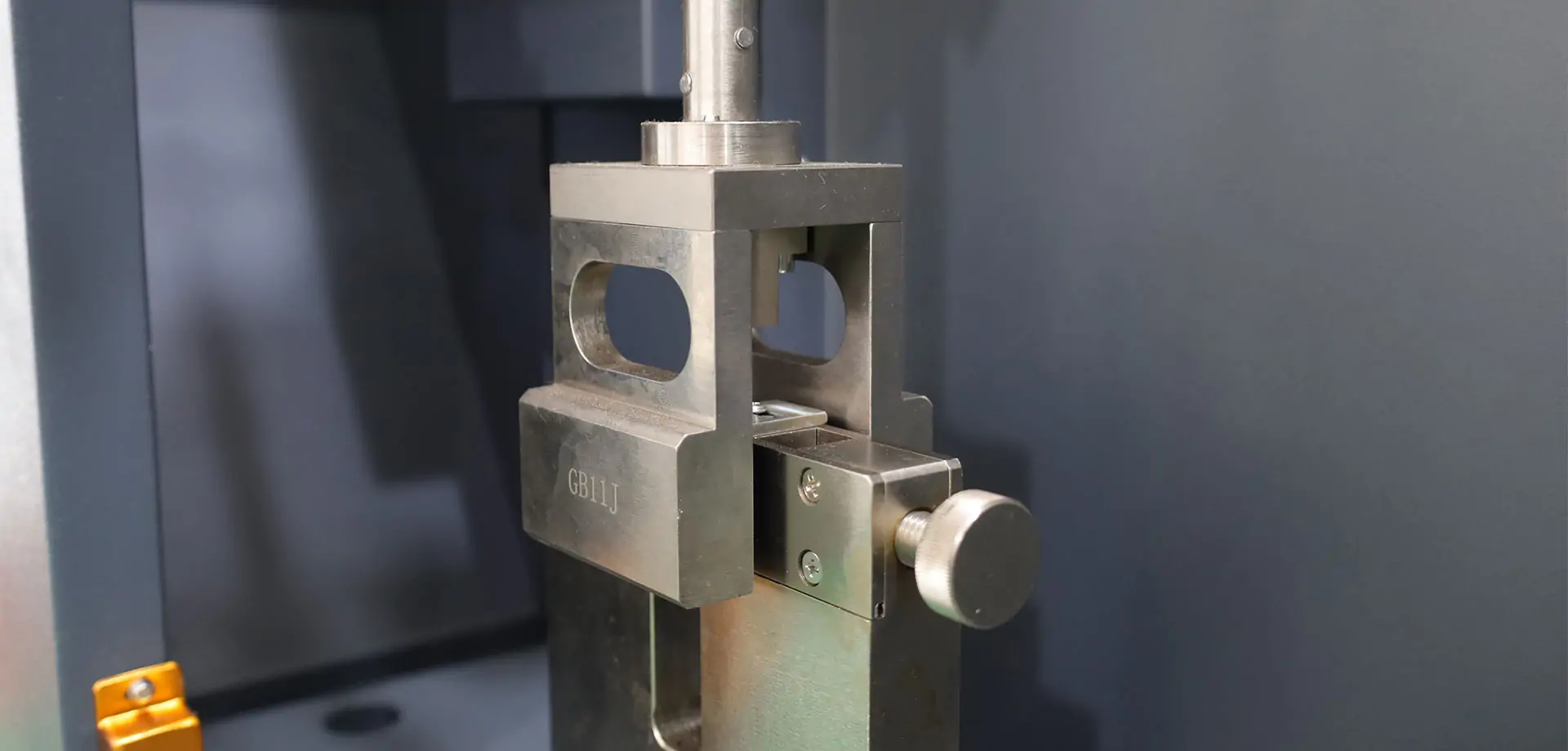

Sample Installation: Secure the sample in a V-shaped or U-shaped fixture to avoid loosening.

Start Testing: Release the pendulum to strike the sample; the device automatically calculates and displays the impact strength.

Data Recording: Repeat the test 3 to 5 times and take the average as the final result.

2.2 Maintenance and Safety Precautions

Regular Maintenance: Lubricate the pendulum bearings quarterly and check for loose fasteners.

Environmental Requirements: The equipment should be used in a controlled environment of 23℃±2℃ and 50%±5% humidity.

Safety Measures: Operators must wear safety goggles during testing and stay clear of the pendulum's swing range.

3. Purchasing Guide: How to Choose Cost-Effective Equipment?

3.1 Define Requirements: Industry and Testing Standards

Industry Matching:

Automotive and aerospace industries: Prioritize high-precision models compliant with ASTM D6110.

Packaging material companies: Focus on ISO 179 standards and ensure repeatability error is ≤3%.

Sample Type: High-impact energy (≥15J) is required for hard plastics, while low-energy models are suitable for soft rubber.

3.2 Core Performance Comparison

Indicator

|

Economy Model

|

Professional Model

|

Energy Range

|

0.5J to 15J

|

1J to 50J (expandable)

|

Accuracy Error

|

≤5%

|

≤1%

|

Data Functionality

|

Basic display

|

Multi-parameter recording, PC analysis software

|

Price Range

|

4,000to4,000to10,000

|

13,000to13,000to26,000

|

3.3 After-Sales Service and Brand Selection

Brand Recommendations: Domestic brands (e.g., MTS, Xinsansi) offer high cost-effectiveness, while imported brands (e.g., Instron, Zwick) provide higher precision but at a higher cost.

Service Guarantees:

Is free installation and training provided?

What is the warranty period for key components (pendulum, sensors)?

Can maintenance requests be quickly addressed?

4. Market Trends: Intelligence and Efficiency Are the Future Directions

With the advancement of Industry 4.0, Plastic Pendulum Impact Testers are moving towards intelligent development:

Automated Testing: Equipped with robotic arms for automatic sample clamping and continuous testing.

AI Data Analysis: Uses algorithms to predict material failure modes and optimize product design.

Cloud Management: Test data is uploaded in real-time to enterprise quality management systems (QMS).

Conclusion

The Plastic Pendulum Impact Tester is the "gatekeeper" for material development and quality control. When purchasing, enterprises should consider their budget, testing needs, and after-sales service to select the right model. For further information on equipment selection or to request free sample testing services, please contact our technical team for a one-on-one solution!

Original Statement: This article is based on industry standards and practical testing experience. Please indicate the source when reprinting.