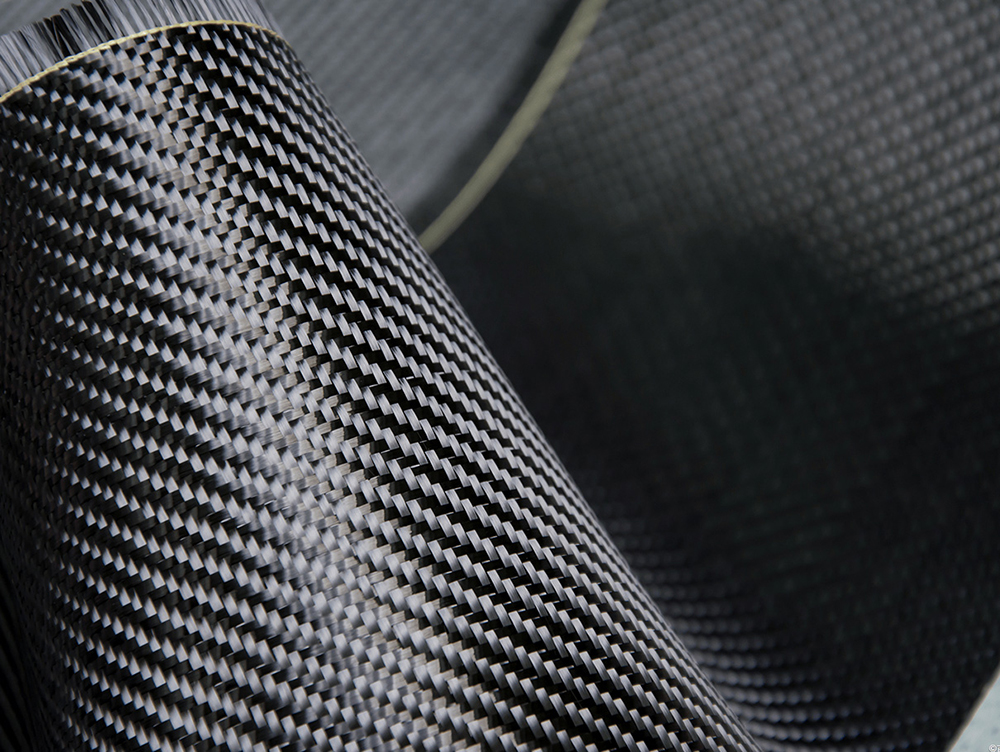

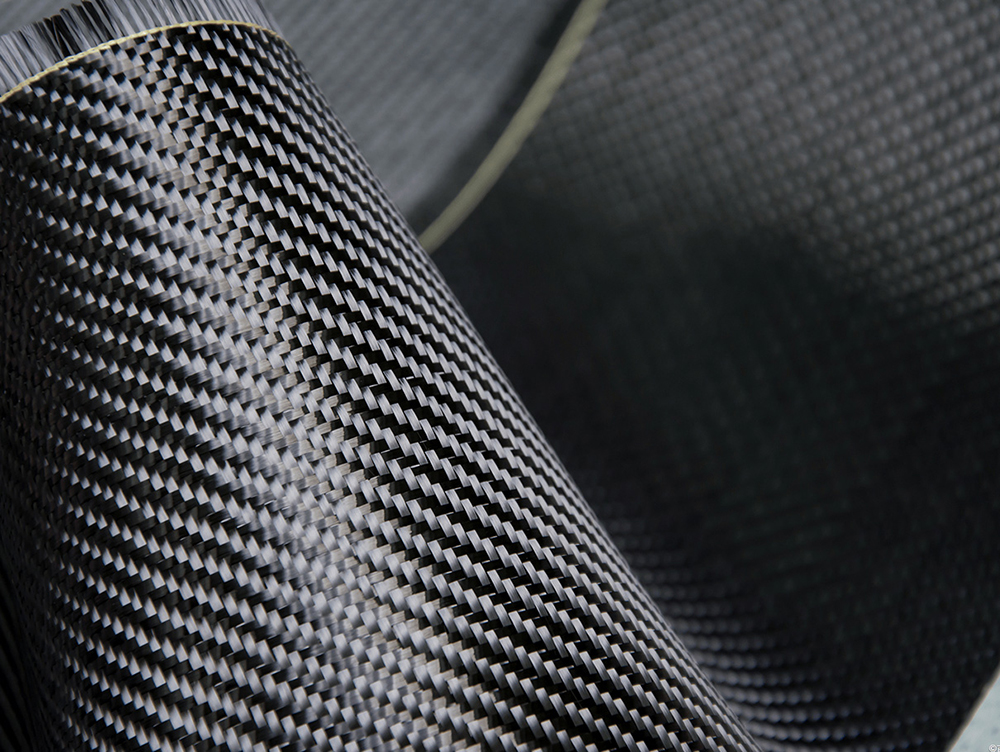

Polymer materials are widely used in automotive, electronics, medical, and packaging industries due to their lightweight, corrosion resistance, and ease of processing. However, the mechanical properties of polymer materials are complex and highly variable, making accurate performance testing critical. Designed specifically for polymer materials, the electronic universal testing machine stands out as a core tool for R&D and quality control, offering high precision, multifunctionality, and intelligent operation.

I. Key Features: Engineered for Polymer Materials, Precision-Driven Efficiency

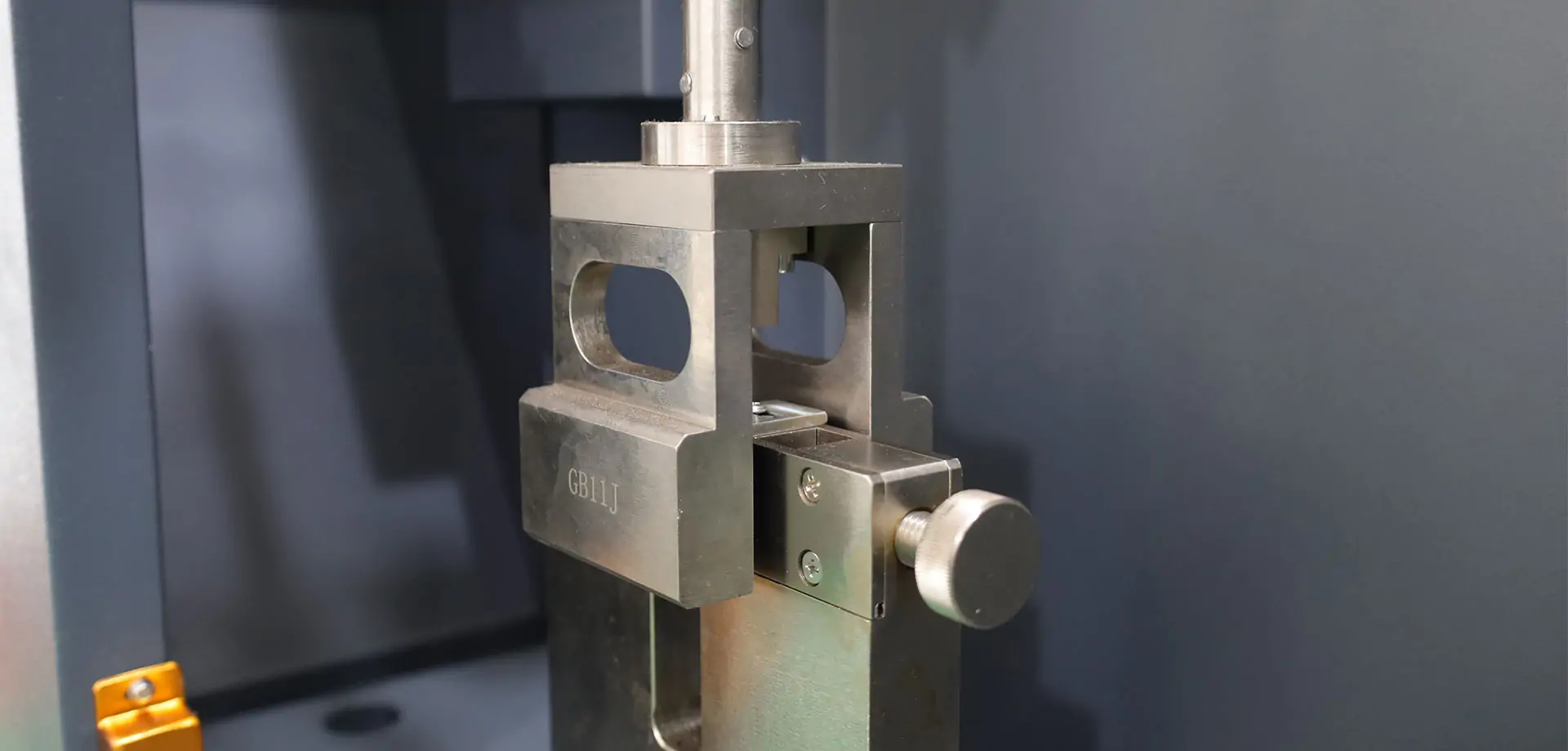

Our polymer material electronic universal testing machine is optimized for the unique characteristics of polymer materials, ensuring accurate and reliable test data. Key features include:

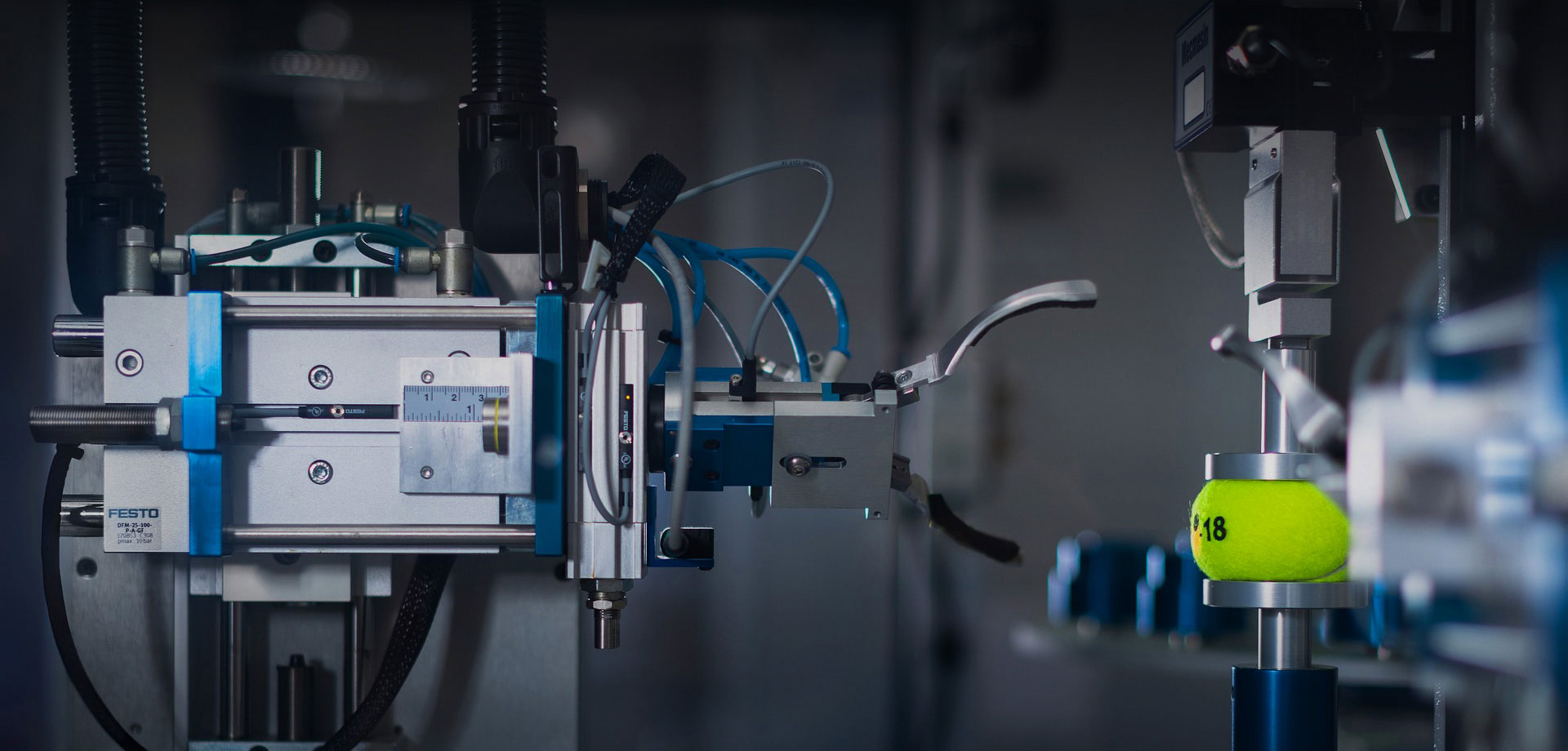

High-Precision Sensors:

Equipped with imported high-accuracy sensors to capture subtle performance variations in polymer materials.

Wide Force Range:

Multiple specifications available, spanning from 0.5N to 100kN, suitable for testing thin films to engineering plastics.

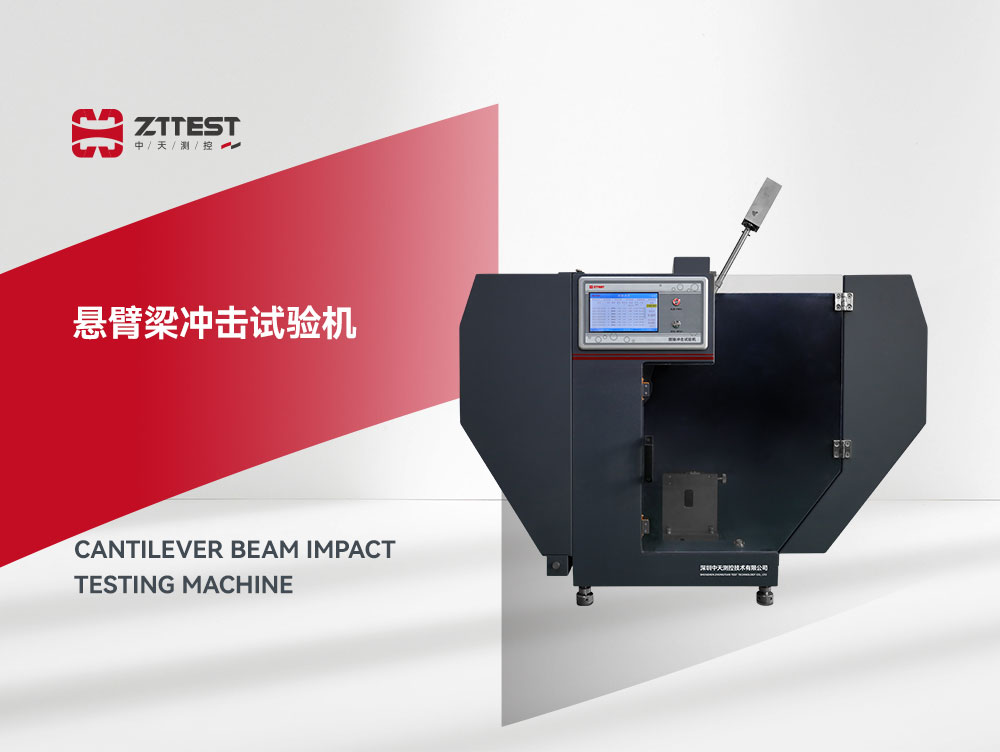

Multifunctional Testing Modes:

Supports tensile, compression, bending, shear, and peel tests for comprehensive mechanical property evaluation.

Environmental Simulation Capability:

Optional high/low-temperature chamber to simulate material performance under diverse thermal conditions, delivering holistic data for real-world applications.

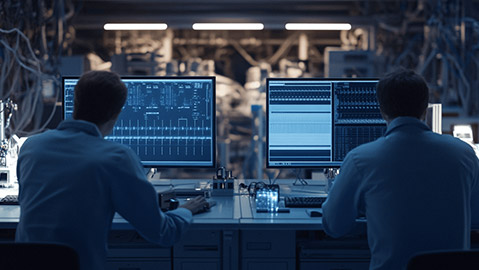

Intelligent Operation:

Integrated professional software enables automated control, real-time data acquisition, curve analysis, and report generation, ensuring user-friendly operation and enhanced efficiency.

II. Industry Applications: Full-Spectrum Support for Polymer Material Innovation

This testing machine plays a pivotal role across polymer material R&D and production processes:

Material Development:

Evaluate tensile strength, elongation at break, elastic modulus, and other properties to optimize material formulations.

Quality Control:

Test raw materials and finished products to ensure compliance with industry standards.

Product Design:

Provide scientific insights for design by analyzing material performance under varying conditions.

Failure Analysis:

Identify root causes of material failures to refine production processes and material performance.

III. Our Advantages: Professional Services You Can Trust

As a leading supplier in polymer material testing, we are committed to delivering high-quality equipment and comprehensive services:

Customized Solutions:

Tailor configurations to meet specific testing requirements for diverse polymer materials.

Expert Technical Support:

Our experienced team provides installation, calibration, training, and post-sales maintenance.

Continuous Innovation:

Stay ahead of industry trends with ongoing upgrades to equipment performance and testing methodologies.

Choosing our polymer material electronic universal testing machine means choosing precision, efficiency, and reliability. Let’s collaborate to drive innovation in polymer materials and advance industry excellence!

Contact us today to explore product details and tailored solutions.