To properly use the universal testing machine for polymer materials, the operator needs to be familiar with the basic structure and function of the equipment, and understand the test process and related precautions.

The following are the general use steps and operation guide of universal testing machine for polymer materials:

I. Introduction of equipment

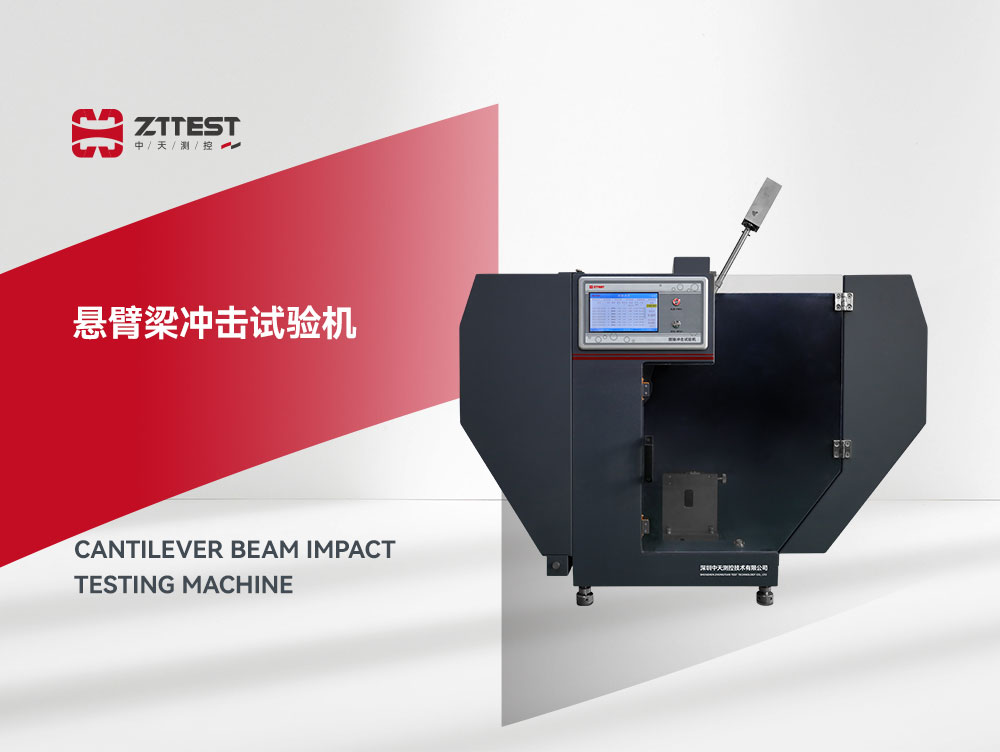

Universal testing machine for polymer materials is a kind of equipment used to test the mechanical properties of materials, applicable to tensile, compression, bending and other mechanical properties test. It is mainly used to evaluate the performance of polymer materials such as plastics, rubber, composites, etc. under different loads.

Second, the use of steps

1. Preparation

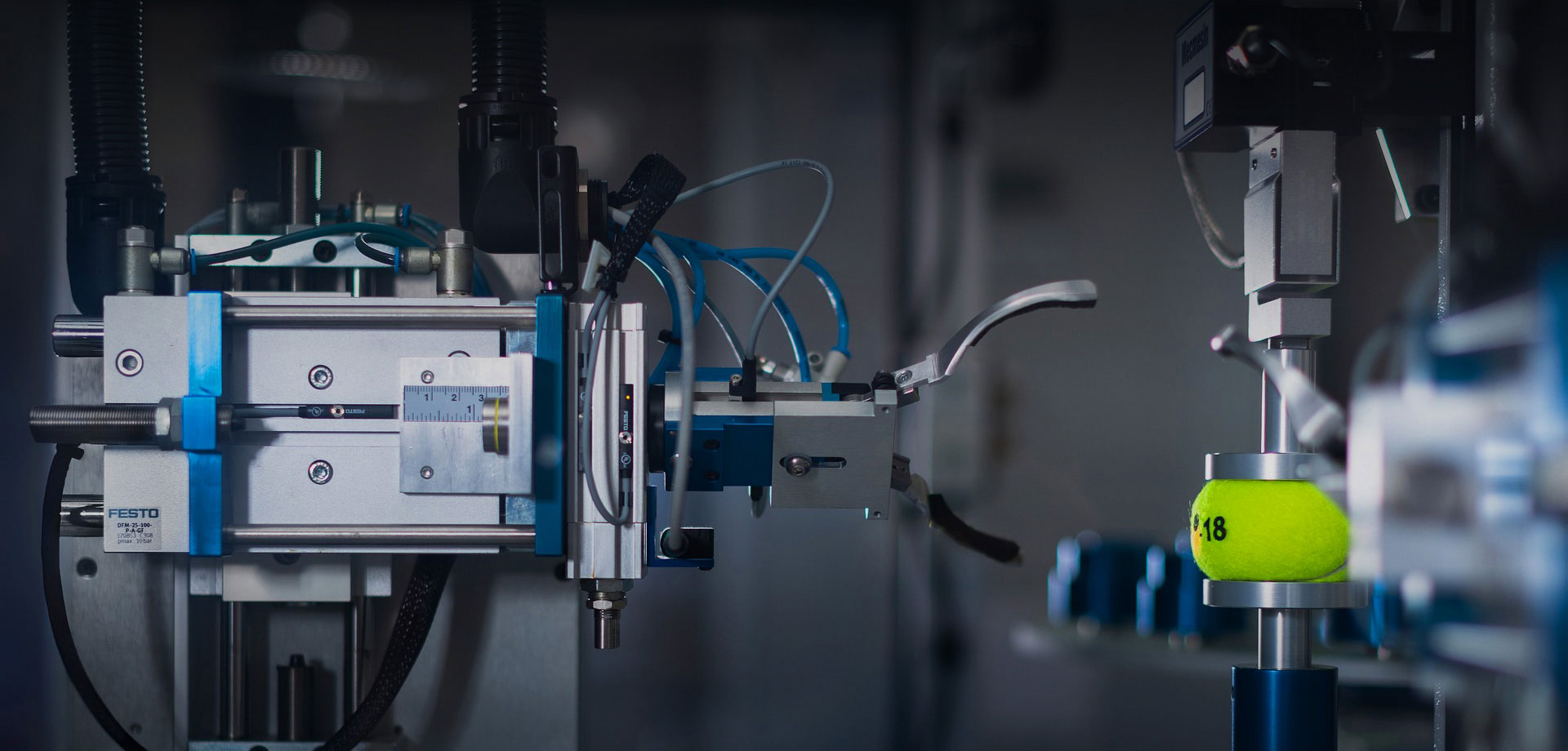

Check the equipment: Before operation, check whether the parts of the testing machine are normal, such as sensors, clamps, loading system, computer control system, etc., to ensure that the equipment is free from damage and failure.

Power supply and gas connection: Confirm that the equipment power supply and gas connection is normal, and make sure it meets the safety standards before turning on the equipment.

2. Sample preparation

Making specimens: Cut and prepare specimens according to the test standards (such as ASTM, ISO standard size and shape).

Measurement of specimen dimensions: Use an accurate measuring tool to record the initial dimensions of the specimen for subsequent calculation of mechanical property parameters.

3. Mounting the specimen

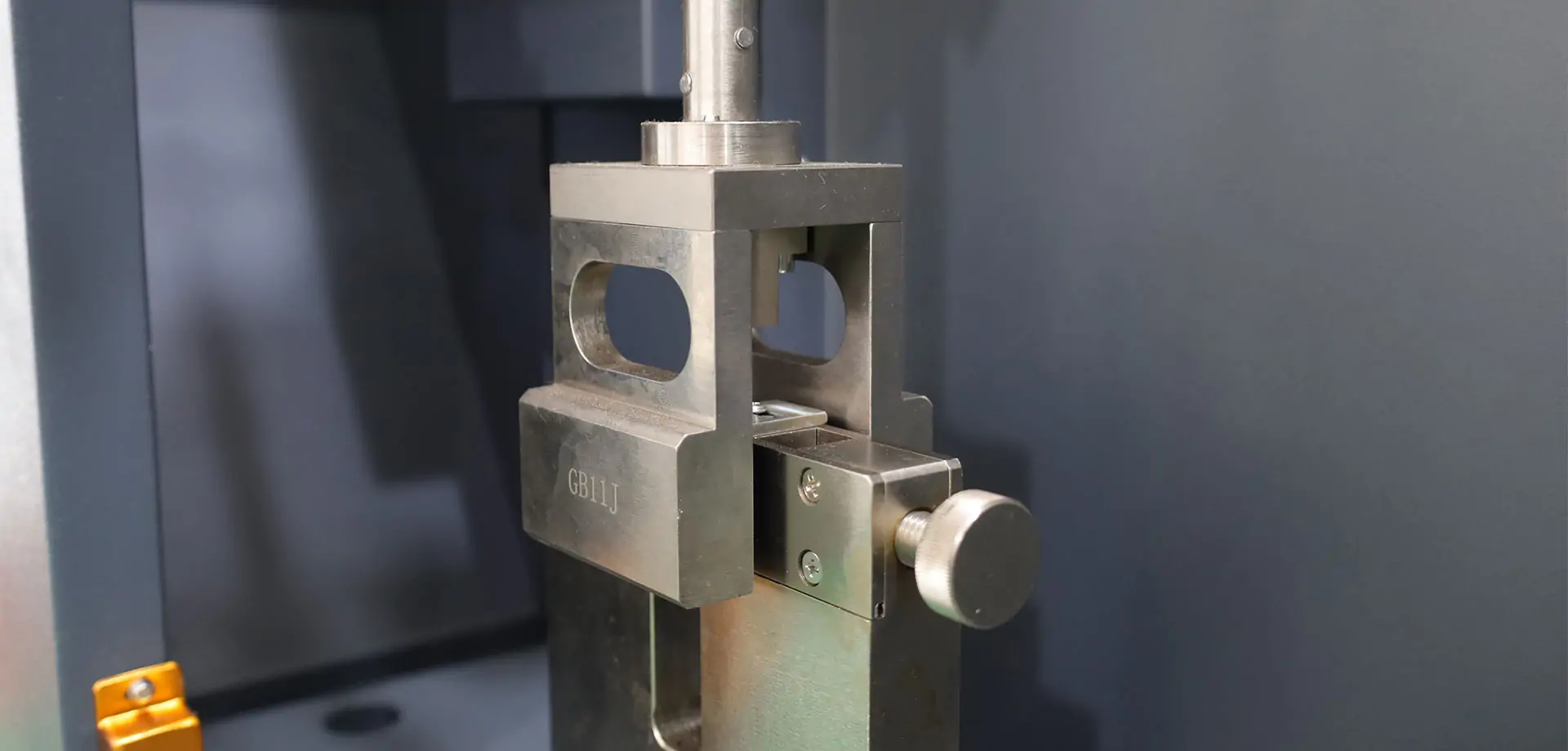

Selection of fixtures: Select the appropriate fixtures according to the type of test (tensile, compression, bending, etc.) and mount them on the equipment.

Fixing the specimen: install the specimen in the fixture correctly and make sure it is fixed firmly to prevent it from sliding or falling off during the test.

4. Setting test parameters

Start the software: open the control software of the universal testing machine and select the appropriate test mode (e.g. tensile test, compression test, etc.).

Input parameters: set the parameters of test speed, loading rate, specimen size, etc. to ensure that the test meets the requirements of relevant standards.

Zero calibration: calibrate the sensor and loading system to ensure the accuracy of the data.

5. Conduct the test

Start the test: After confirming that all parameters are set correctly, start the test. The tester will automatically apply load, record data such as force and displacement, and generate real-time curves.

Monitor the process: During the test, the operator should always pay attention to the status of the specimen and the operation of the equipment, so as to stop the test in time in case of any abnormality.

6. Data recording and analysis

Generate report: After the test, the equipment will automatically generate force-displacement curve, stress-strain curve, etc., and the user can export the data according to the test requirements.

Analyze the results: analyze the mechanical properties of the specimen, such as tensile strength, elongation at break, modulus of elasticity, etc., according to the curve and data.

Third, the use of precautions

1. Safe operation: When operating, make sure that there is no personnel around the equipment to contact the fixture and transmission parts to avoid accidental injury. Wear appropriate protective equipment (such as safety glasses).

2. Equipment Maintenance: Regularly check the electrical system, mechanical parts and sensors of the equipment to ensure that the equipment is always in good condition and prolong its service life.

3. Fixture Selection: Choose the fixture that is suitable for the test material and the shape of the specimen to avoid inaccurate data or specimen sliding due to improper clamping.

4. Standard reference: the test process should be in strict accordance with the relevant standards for operation, such as ASTM D638, ISO 527, etc., to ensure that the test data are comparable and reliable.

Common problems and solutions

Abnormal data: Check whether the sensor is calibrated or whether the data is distorted due to specimen sliding.

Equipment noise: may be due to the mechanical parts of the equipment is loose or lack of lubrication, need to maintain in time.

Undesirable destructive position of specimen: check whether the fixture is clamped correctly and adjust the fixture position and pressure.

Summarize

The universal testing machine for polymer materials plays an important role in material property testing. Through correct operation steps and parameter settings, accurate mechanical property data can be obtained, providing a reliable basis for material research and quality control. Operators should familiarize themselves with the functions and operating procedures of the equipment, and regularly maintain and repair the equipment to ensure the long-term stable operation of the equipment.