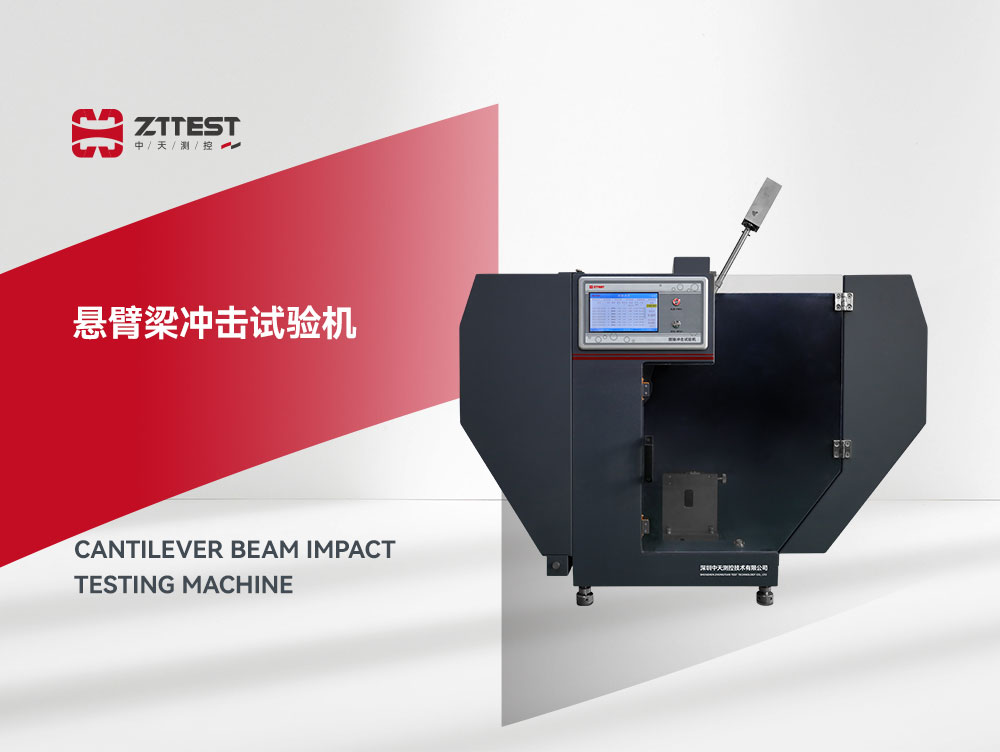

Electronic Universal Tensile Tester is a kind of equipment used to test the performance of materials under different mechanical conditions such as tensile, compression, bending, etc. It is widely used in the fields of scientific research, quality control, production and material development. By measuring the stress-strain relationship of materials under different forces, it is able to evaluate the strength, ductility, elastic modulus and other key properties of materials. Compared with the traditional mechanical tensile testing machine, electronic universal tensile testing machine has higher precision, wider test range and more intelligent operating system, is the indispensable equipment for modern material testing.

First, the main features of electronic universal tensile testing machine

1.High precision and reliability

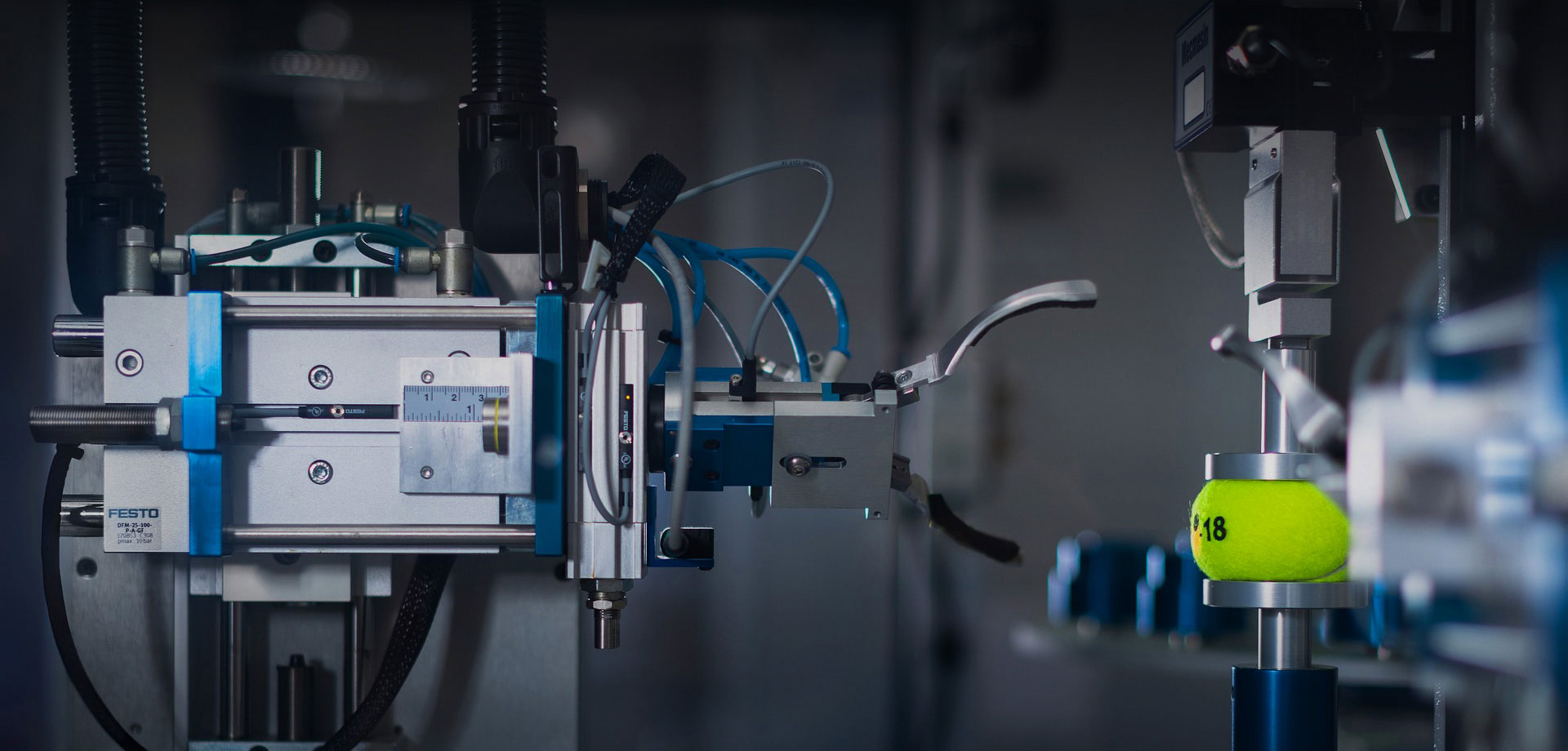

Electronic universal tensile testing machine adopts high-precision force transducer, displacement sensor and control system to ensure the accuracy and repeatability of test data. The equipment can provide from small to large tensile force measurement, suitable for different materials and specifications of the sample test.

2.Intelligent control system

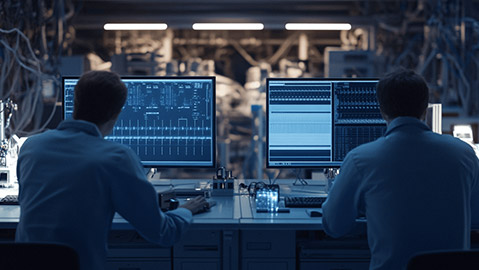

Modern electronic universal tensile testing machine is equipped with intelligent control system, users can set parameters and real-time monitoring through the touch screen or computer software. The system automatically records data and generates stress-strain curve, simplifying the process of data analysis.

Support a variety of test modes, such as tensile, compression, bending, shear, etc., flexible operation and adaptability.

3. Wide testing range

The equipment is suitable for testing a wide range of materials, including metals, plastics, rubber, composites and so on. By replacing different fixtures, different types of tests can be conducted to meet the needs of a wide range of applications.

4.Conform to international standards

The electronic universal tensile testing machine conforms to international standards such as ISO, ASTM, etc., which ensures the reliability and authority of the test results. Its accuracy and repeatability meet the testing requirements of various industries.

5.Data Acquisition and Analysis

During the test, all the test data are collected in real time through the computer system, which can automatically generate data charts and reports, greatly improving the efficiency of data processing.

Second, the main use of electronic universal tensile testing machine

1. Material research and development and experiment

In scientific research institutions and university laboratories, electronic universal tensile testing machine is commonly used in the mechanical properties of materials testing, to help researchers develop new materials or improve existing materials.

2.Quality control and product inspection

In industrial production, electronic universal tensile testing machine is widely used for quality testing of raw materials and finished products to ensure that the products meet the quality standards. Especially in plastics, metal, rubber and other industries, the strength, elongation, tensile properties of the product is a key indicator of quality control.

3.Industrial applications

Materials used in various industrial fields, such as automotive, construction, aerospace, etc., rely on the electronic universal tensile testing machine to carry out testing of material properties. It helps manufacturers and engineers analyze the mechanical properties of materials in different environments to ensure their reliability in actual use.

4. Testing and Standardization

Many industries require materials to meet international standards, and electronic universal tensile testers can provide accurate test data to ensure that products comply with ISO, ASTM and other relevant standards.

Operation Steps

1.Preparation

Before using the electronic universal tensile testing machine, first check the equipment components are intact, such as sensors, loading systems, control panels, etc., to ensure that the equipment operates normally.

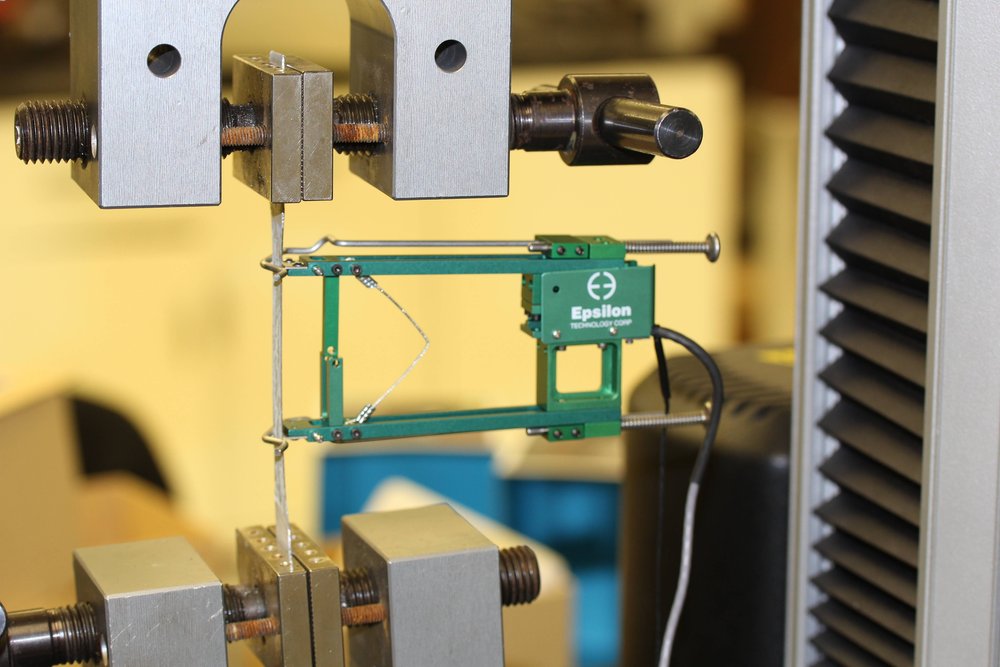

Install and calibrate the force transducer to ensure accurate data during the test.

2. Sample Preparation

Prepare the samples according to the test requirements to ensure that their size and shape comply with the standards (e.g. ASTM, ISO regulations).

The sample surface should be smooth and free of defects to ensure the accuracy of the test data.

3. Sample Mounting

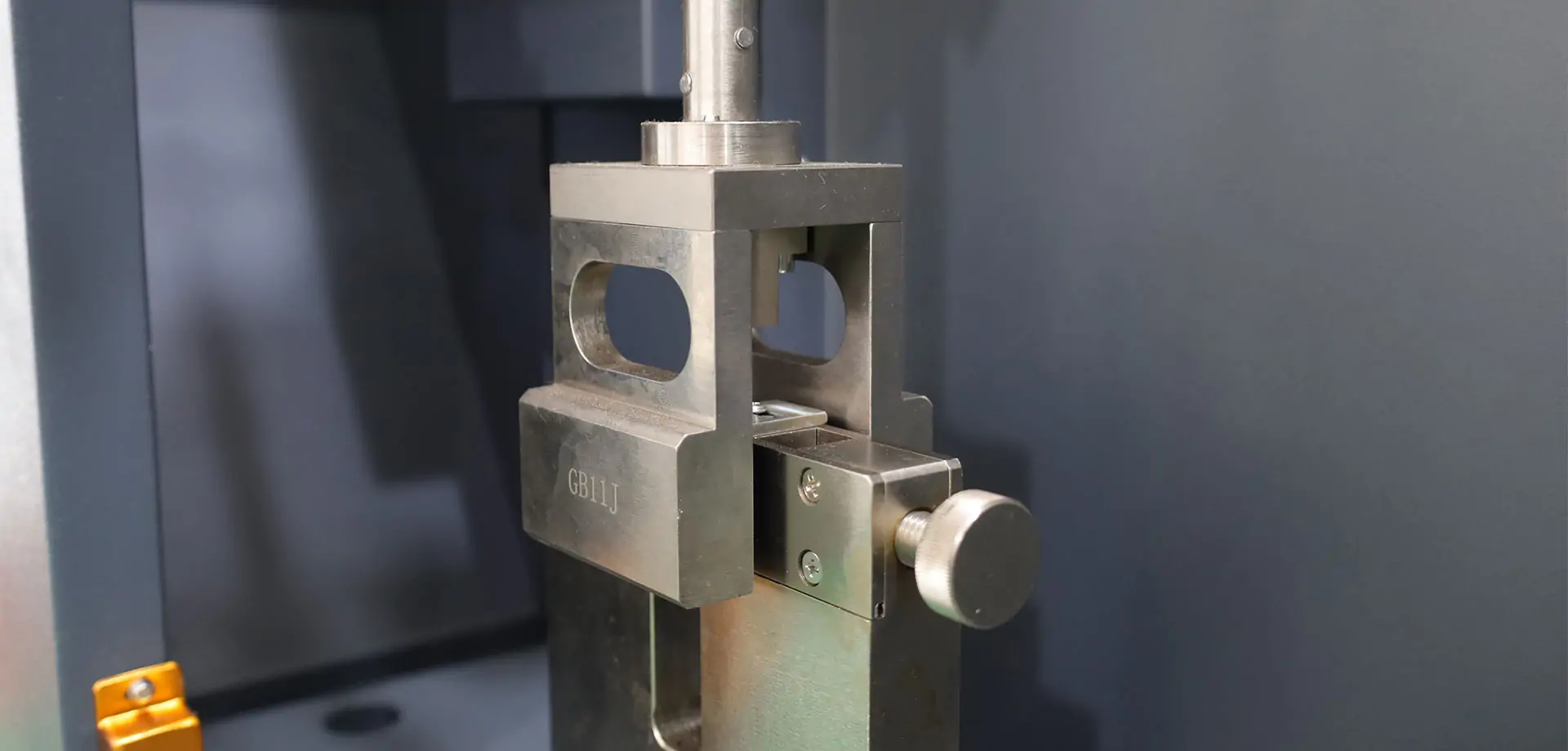

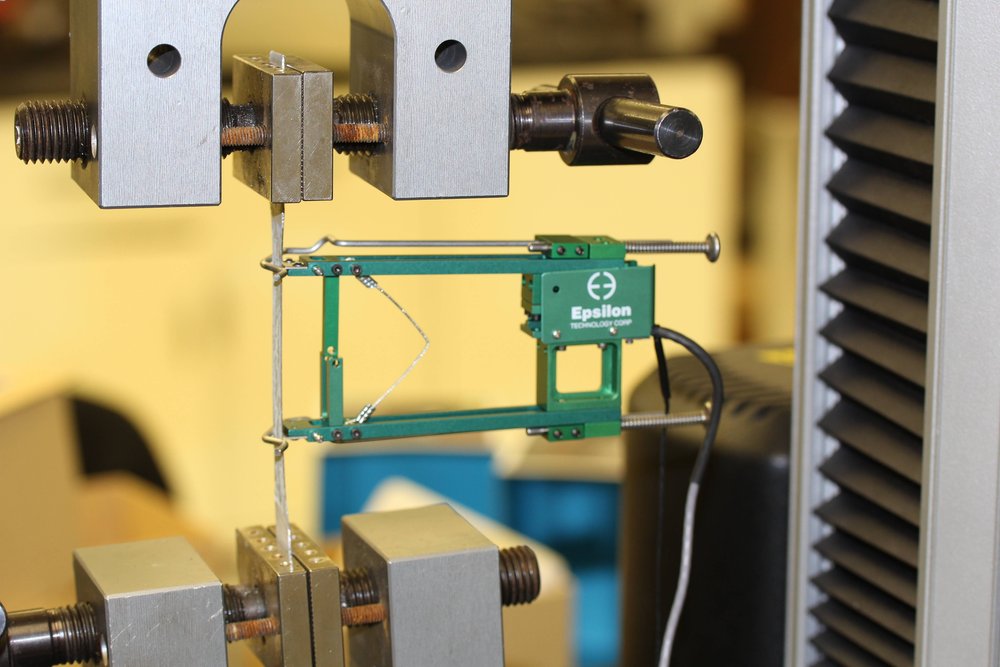

Mount the specimen in the fixture of the equipment to ensure that the specimen is firmly mounted and centered.

For different types of tests, select the appropriate fixture (such as tensile fixture, compression fixture, bending fixture, etc.).

4. Setting test parameters

Input test parameters in the equipment control system, including test speed, loading rate, test time, etc..

According to the characteristics of the material and test requirements to set the appropriate temperature and environmental conditions (such as high temperature, high humidity environment).

5.Starting Test

Start the testing machine, the equipment will automatically apply the load and record the data. During the test, observe the real-time data displayed by the equipment to ensure that the test is carried out smoothly.

6.Data Recording and Analysis

After the test is completed, the device automatically records the test data and generates the stress-strain curve. Users can view and analyze the data, generate reports, and export test results.

7. Equipment cleaning and maintenance

After the test, clean up the equipment, especially the sensors and fixtures, to prevent sample residues from affecting subsequent tests. Regularly check the operating condition of the equipment to ensure its long-term stable operation.

Fourth, the selection of electronic universal tensile testing machine considerations

1. Equipment precision and stability

When choosing the equipment, make sure it has high-precision force measuring system and stable performance, and can meet the long-term high-frequency testing needs.

2. Intelligent control system

Choose the equipment equipped with intelligent control system, which can simplify the operation process, improve the efficiency of data processing, and at the same time support the automation of data acquisition, analysis and report generation.

3. Test range and function

Confirm whether the test range of the testing machine meets your needs, including maximum loading force, test speed, sample size, etc.. If you need a variety of testing modes, choose a multi-functional, flexible configuration of the equipment.

4. After-sales service

Choose the manufacturer who provides perfect after-sales service to ensure the installation, commissioning, operation training and regular maintenance of the equipment. Regular calibration and maintenance of the equipment is the key to ensure the accuracy of the test.

5. Equipment compliance

Ensure that the equipment meets the international or industry-related testing standards (such as ISO, ASTM, etc.) to ensure the authority and reliability of the test data.

V. Summary

Electronic universal tensile testing machine is a powerful material testing equipment, widely used in scientific research, quality control, industrial production and other fields. Through correct operation and selection of suitable equipment, enterprises and scientific research institutions can effectively test the mechanical properties of materials, optimize the production process and ensure product quality. Choosing a reliable equipment supplier can help you improve testing efficiency, reduce operating costs, and ensure the accuracy and reliability of test results.